OpenAI Books TSMC’s A16 Process Capacity for Custom Chips Powering the Sora Video Generation Model

Semiconductor manufacturing giant TSMC is currently developing angstrom-level chip processes, with the term "angstrom" referring to a unit of length equal to one-tenth of a nanometer. Thus, TSMC's A16 process equates to a 1.6 nanometer process.

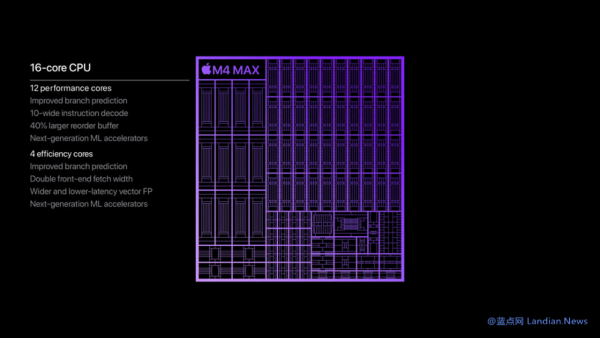

Apple is typically the first in line to secure TSMC’s cutting-edge production capacity, and the A16 process is no exception. TSMC is expected to mass-produce A16 chips by 2026, which will then be used in Apple’s A and M series chips.

Recent reports reveal that OpenAI will follow Apple as an early customer of TSMC's A16 process. OpenAI has booked this capacity for TSMC to manufacture its self-developed chips, specifically designed for OpenAI’s video generation model, Sora.

Initially, OpenAI considered developing and manufacturing these chips in-house, understanding the volume of chips it would need in the future. From a certain perspective, setting up its own chip factory could have been a viable option.

However, OpenAI eventually decided to shift towards a strategy of developing its chips and then outsourcing the manufacturing to TSMC. The chip development is a collaborative effort with Broadcom and Marvell Technology, focusing on Application-Specific Integrated Circuits (ASICs) tailored for AI workloads.

These ASICs are expected to be produced using TSMC’s 3nm process in 2024 or 2025. With the transition to TSMC's mass production A16 process in 2026, the new technology will ensure optimal chip performance.

By booking TSMC’s A16 process capacity, OpenAI has also become a strategic partner of TSMC. This partnership will allow OpenAI to access professional expertise in chip design and manufacturing capabilities, paving the way for large-scale production of AI chips.