Intel's First Batch of 18A Process Products Rolls Off the Line and Successfully Boots Up, Production Expected to Start in 2025

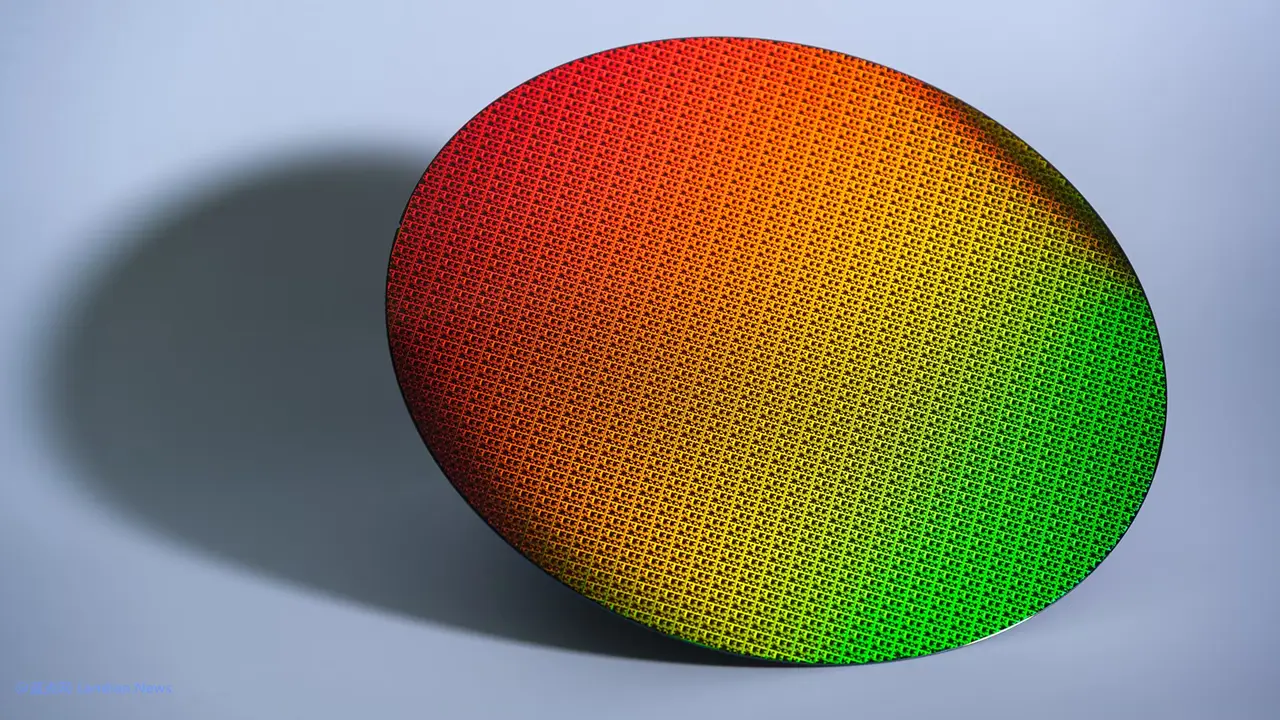

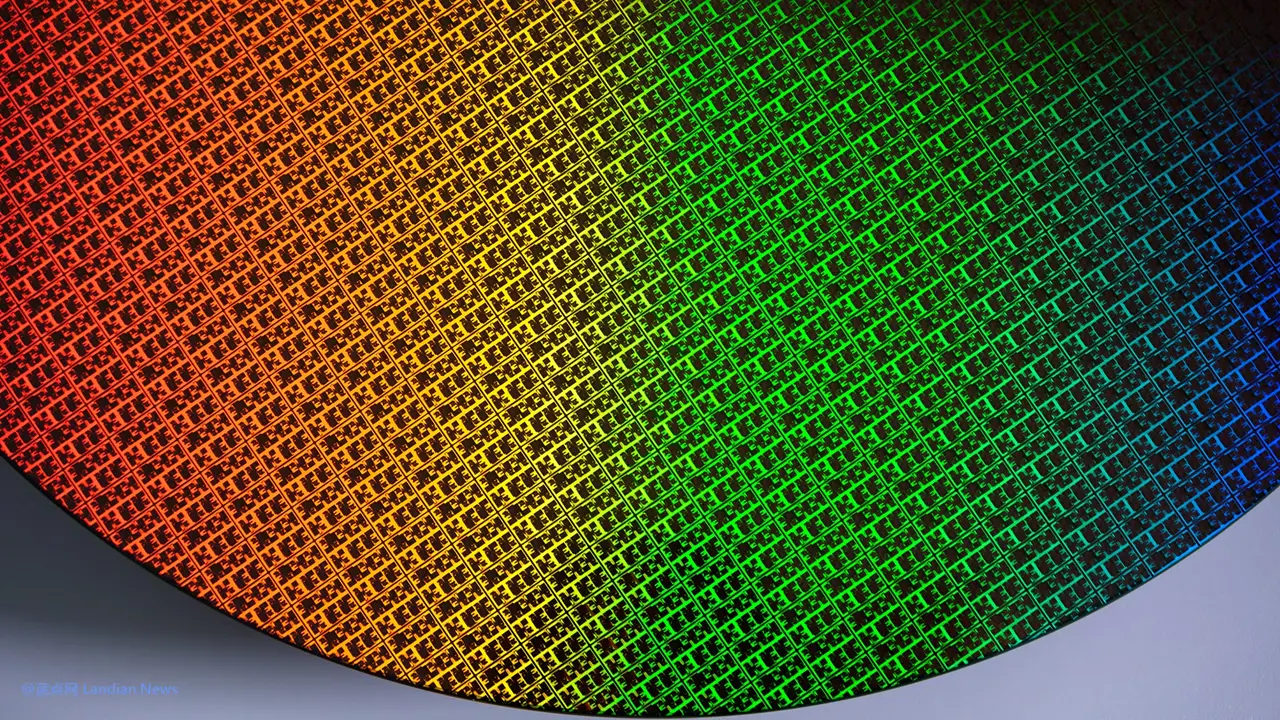

In recent times, Intel has been in the news for a number of setbacks, including processor issues and significant layoffs. However, there's finally some good news on the horizon: the much-anticipated Intel 18A process has essentially been completed. The first batch of AI PC processors and server processors based on the 18A process have rolled off the production line and successfully booted up the operating system.

The Intel 18A process corresponds to a 1.8 nanometer level technology, a key component of Intel's foundry plan. This is significant as TSMC is set to launch its 2 nanometer process in 2025. If Intel manages to master the 18A process, it could mean capturing market share from TSMC's clientele.

Currently, Intel is utilizing the 18A process for its AI PC processors, Panther Lake, and server processors, Clearwater Forest, both of which are expected to start mass production in 2025.

Intel has also introduced the 1.0 version of its Process Design Kit (PDK) to third-party clients. This move is aimed at enabling clients who use Intel's foundry services to design their own chips based on the PDK. Intel anticipates that its first external customer will debut an 18A design in the first half of 2025. Assuming there are no errors or other defects, Intel's foundry could start mass production for clients by the first half of 2026.

This is great news for fabless clients and the industry as a whole, given that the current advanced manufacturing processes are dominated by TSMC and Samsung. TSMC's advanced process orders are notoriously slow, with most of its capacity reserved for Apple, leaving other clients facing long waits and price increases.

If Intel's 18A process can compete with TSMC's 2 nanometer process, many fabless chip manufacturers might turn to Intel for foundry services. After all, increased market competition usually benefits the clients.

Technologically, the Intel 18A is the second manufacturing technology after Intel's 20A to use the all-gate RibbonFET transistor and backside power supply (PowerVia). This is particularly important for data center products as it helps reduce power consumption and save on electricity costs.

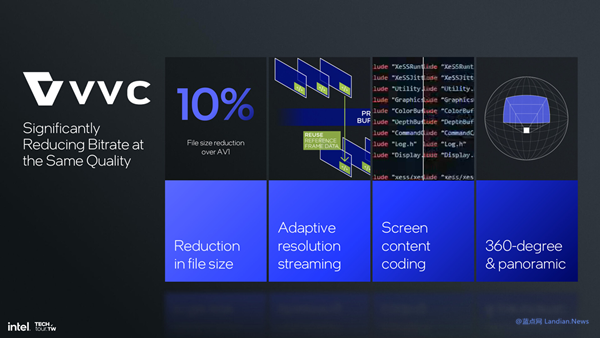

Compared to the 2 nanometer process, Intel's 18A hopes to optimize the RibbonFET design and make other enhancements, such as improving performance per watt by 10%. Thus, data centers extensively using Intel's 18A products could potentially see a significant reduction in electricity costs.

Moreover, Intel's 18A has advantages over TSMC's 2 nanometer process, in that it can accommodate a comparable number of transistors and performance, but with other innovative technologies, it could potentially outperform TSMC's 2 nanometer process in overall performance.