CMFS2023 Reveals Ambitious Plans for 1PB SSDs, But Challenges Remain for NAND Scaling and Materials

This month, the China Flash Market Summit (CMFS2023) took place in Shenzhen, featuring key industry players such as Samsung, Yangtze Memory, Micron, Arm, Kioxia, Intel, Unigroup Spreadtrum & RDA, and Solidigm.

Samsung's Cautious Approach to NAND Technology

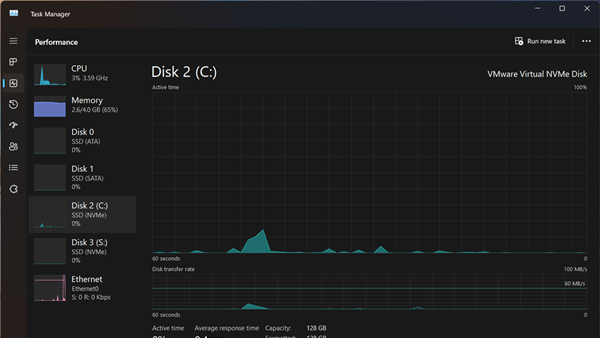

Samsung currently holds the top position in global flash memory chip shipments and revenue. Despite this, the company has been cautious in adopting QLC flash memory, raising questions about the timeline for PLC, HLC, and OLC technologies. Samsung believes that a 1PB solid-state drive could become a reality within the next 10 years, requiring advances in stacking and packaging technologies.

Expanding 3D NAND Capacity Through Scaling

Samsung anticipates that increasing the physical and logical scaling of 3D NAND will be crucial for future developments. Physical scaling refers to reducing the volume of flash memory cells, allowing for more NAND layers to be stacked. Logical scaling, on the other hand, involves increasing the number of bits stored per NAND cell.

The company expects that advancements in 3D NAND IC packaging technology, combined with physical and logical scaling innovations, will push SSD capacities to 1PB (1024TB or 1048576GB) within the next decade.

Samsung's Conservative Timeline and Focus on Controllers

Samsung has been conservative in releasing new flash memory technologies. In 2017, they released a 30.72TB 3D TLC SSD, followed by a 64TB SSD in 2019, and a 128TB 3D QLC NAND SSD prototype in 2021, which did not reach mass production.

The company's caution with 3D QLC NAND is primarily due to their focus on innovating flash memory controllers to bring 3D QLC NAND to the mainstream market. Samsung believes that current 3D QLC NAND controllers are not yet ready for widespread use.

Kioxia (Formerly Toshiba Memory) Embraces NAND Logical Scaling

Kioxia has been more enthusiastic about NAND logical scaling, discussing 5-bit bpc PLC NAND as early as 2019. Kioxia engineers have also demonstrated 6-bit bpc 3D HLC NAND and believe that 8bpc OLC NAND memory is possible.

To store 6 bits per cell, NAND cells must maintain 64 voltage levels, while 8bpc OLC 3D NAND requires 256 voltage levels. Each additional bit per cell presents significant challenges for manufacturers.

The Challenges of NAND Scaling: Materials, Costs, and Temperature

The main difficulties in NAND scaling lie in the materials used. Manufacturers must find materials capable of storing 64 or 256 voltage levels without interference. These materials must also be easily synthesized in large quantities to meet demand.

Furthermore, manufacturers must manage the temperature of 3D NAND cells with multiple voltage levels, as keeping temperatures within reasonable ranges becomes increasingly difficult with more bits per cell.

Lastly, reliable flash memory controllers with more complex ECC algorithms are needed to handle the increased computational requirements. This raises controller costs, and manufacturers must find ways to address these cost concerns.

The Future of NAND Scaling: A Matter of Time

Ultimately, these challenges will be resolved as technology advances, but it may take time to overcome these obstacles. For now, consumers must wait patiently for the next breakthroughs in NAND scaling and SSD capacity.